The construction of underground pipes and tunnels requires careful planning and excavation. Pipes have to maintain a consistent grade along the length of the system. Crests and valleys in the pipe system can block or slow down the liquid flow inside, resulting in clogs that can be expensive to fix. To accurately set the grade of a pipe run, underground contractors use a piece of equipment called a pipe laser.

A pipe laser is a type of construction laser that is used to measure and determine the correct grade for pipes. Pipe lasers are used as a sort of electronic level. Essentially, this equipment shoots a high-powered beam of light at a predetermined angle to establish the appropriate grade of a construction project. In this guide, you can learn more about what a pipe laser is used for, how to use it and the types of pipe lasers available.

Who Uses Pipe Lasers?

Primarily, pipe lasers are used within the underground utility industry by utility contractors, general contractors and municipalities. These teams use pipe lasers in the installation of a variety of underground gravity flow pipes, including sewer pipe systems, storm drains, and the manholes and access points that connect to them.

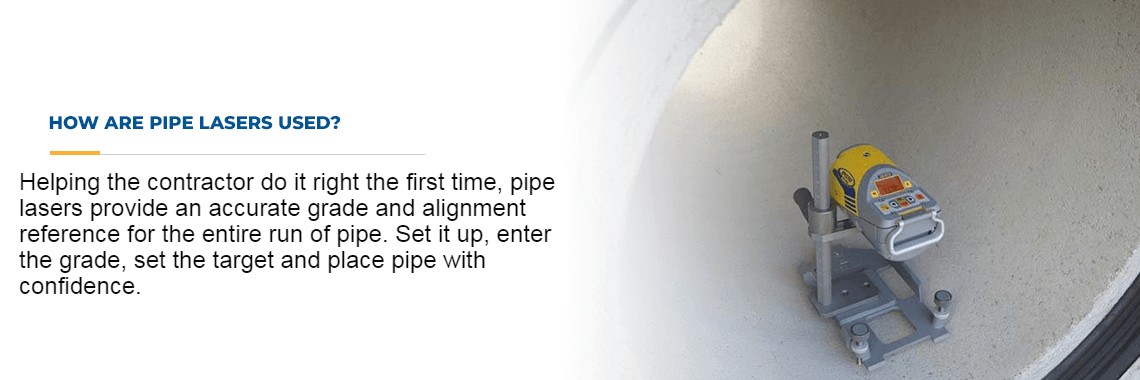

How Are Pipe Lasers Used?

To understand the function and purpose of a pipe laser, it is essential to first understand pipe grades. A pipe grade is the incline or decline at which a pipe is set, and is expressed as a percentage. The grade of the pipe helps manage liquid flow in underground construction projects. This percentage is calculated by dividing the elevation difference by the run of pipe.

For example, if a 100-foot section of pipe is set so the beginning and end have an elevation difference of 4 feet, the grade would be 4%. Most pipes are set at a low-percentage grade, which is sufficient for the purposes of liquid flow. The important part is that the grade is consistent throughout the run of pipe to ensure steady flow and prevent blockages and reduced capacity.

In older land survey techniques, grade had to be carefully measured, calculated and tracked using wooden stakes, string lines, carpenter levels and plumb bobs. This process was time-consuming, and it required the contractor to hire a surveyor to set accurate reference points throughout the jobsite. One error could result in significant problems in grade consistency, potentially resulting in long-term issues with the laid pipe. However, new tools have made it easier to set pipe grades correctly. This is where pipe lasers come in.

Pipe lasers make pipe leveling simpler because they provide an accurate grade reference without the need for previously mentioned stakes, string lines and plumb bobs. This technique substitutes manual geometric calculations with basic physics, providing highly accurate results using a combination of laser technology and self-leveling compensation. The highly visible laser beam is easy to use on varying lengths of pipe and with the help of plastic or electronic targets can be effective over a distance of up to 500 feet.

The pipe lasers look like small cylinders with a laser on one side and a digital display and control buttons on the other. They’re typically small enough to fit inside a 8-inch pipe, but rugged enough to be used in high-activity construction sites. These lasers have built-in feet, but may also be mounted on stands or adapters to place them at specific heights or locations. Pipe lasers come with built-in self-leveling systems to ensure that laser beam is akways accurate to the desired line and grade.

How Are Lasers Used in Construction?

Pipe lasers are just one example of laser-powered tools workers may use. A variety of lasers are used throughout the construction industry for the following purposes:

- Grading: Construction teams often use laser-based display and grade control systems for grading and earthmoving. These lasers provide a visual guide in grading operations where earth needs to be moved to achieve a specific slope. In some applications, the laser beam is a flat plane to visualize the grade and slope desired. Regardless of the specific laser used, these systems provide an accurate guide that can speed up grading operations, improve accuracy and increase profitability.

- Leveling: Laser levels provide a flat reference plane between two points, allowing for better control of level and elevation in a job site. Laser levels are excellent for use in applications where a traditional optical level is insufficient — such as leveling a large surface area or length, like an excavation project or a concrete pour.

- Alignment: Lasers are often used as alignment references on job sites in both the horizontal and vertical planes. Lasers are used to align concrete forms, suspended ceilings and interior walls and are excellent visual references for aligning features before placement.

Choosing a laser customized to the needs of a specific application, such as a pipe laser, enables workers to complete projects with the accuracy and efficiency necessary for a high-quality job.

The Benefits of Pipe Lasers

While pipe lasers are small, they are highly functional. Pipe lasers are waterproof and rugged enough to handle high-activity construction sites, which makes them perfect for full-function leveling in construction applications. If you’re considering using a pipe laser on your project, check out some of the benefits they offer in above- and below-ground applications:

- Speed: Pipe lasers are quick and easy to use. They can go inside or outside a pipe to provide a visual level to ensure the pipe is graded evenly. Using a pipe laser gives you reliable measurements more quickly than using manual methods, which can cut back on project time, save labors costs and improve turnaround speed.

- Accuracy: Because they remove most of the manual measuring process, pipe lasers ensure a consistent and accurate grade for proper pipe placement. The target and alignment system also add accuracy keeping the pipe on the proper alignment from one manhole to the next.

- Ease-of-use: Pipe lasers are designed for easy single-user operation. Through the use of radio remotes and computerized leveling, modern pipe lasers can easily be used by a single person, allowing labor to be reallocated for maximum productivity and profitability.

- Operability: Pipe lasers offer 30 hours to 50 hours of continuous operating time, which helps maximize productivity by cutting down on interruptions and battery costs.

- Cost: Pipe lasers pose an upfront investment, but they save substantial money in the long run. The technology speeds up the survey and excavation process, saving money on labor, and the accuracy of this technology reduces the potential for costly rework.

These benefits make pipe lasers a valuable addition to any construction project. It is important to note that a skilled operator can capitalize on these benefits the most. While pipe lasers are easy to use, skilled personnel are needed to operate them correctly to ensure the installation is accurate. The laser operator doesn’t need to perform the level of work and calculation required in manual grading processes, making it easy to train installation personnel to use pipe laser equipment properly.

Types of Pipe Lasers

Pipe lasers are typically available in several models differentiating each model with more advanced features and a highly visible green beam laser. Although red beam lasers have been around since the mid 1960’s, advanced diode technology has made it possible to produce a green beam laser that is highly visible extending beam clarity at longer distances and in high sunlight situations.

If you’re looking for high-end functionality, the Spectra Precision laser is the best choice in pipe laser technology. The Spectra Precision laser is designed for challenging job site applications, with a large, clear display and a rugged, nickel-plated design. This pipe laser has a grade range of -15% to 40% and is programmed with 10 different languages to make it functional for a wide user demographic. SITECH Southwest provides the Spectra Precision DG813, DG613 and DG613G models, so your company can choose the right features, benefits and price that works best for your job. If you have a short term project, SITEH Southwest has pipe lasers in their rental department for weekly or monthly equipment rentals.

How to Use a Pipe Laser

Pipe lasers make the pipe grading process quick and easy. But how do you set up a pipe laser? Below is a simple guide to using a pipe laser in the field:

- Calculate the grade: Before using the laser level, first determine the grade. This is usually pre-calculated during the planning stage, but it is easy to measure if not. Simply measure the distance between the two manholes you are grading, called the run, then determine the elevation contrast. Divide the elevation difference by the run, and use that percentage to determine the grade.

- Place the laser: Now that you have the grade, you can set up the pipe laser. The laser can be placed on the inside or outside of the pipe, depending on the type of pipe you’re using. You may also set up the laser on a tripod, spreader bar or other type of mount if appropriate for your application. However you decide to station the laser, be sure that it is firmly in place.

- Level the laser: Once the laser is in place, level it. Many modern pipe lasers calibrate themselves, making this step easy. If you don’t have a self-calibrating laser, you will need to manually level the laser. Using a bubble-level, adjust the pipe laser so that it is level to the ground.

- Set the laser: Once the laser is placed and leveled, turn it on. This is where it is important to know how to work out a pipe laser reading. Using the digital display and the grade calculated, set the pipe laser to match the needed grade. Positive grades will indicate an incline, while negative grades indicate a decline. As soon as the value is entered, the laser will self-adjust to shoot a laser beam down the length of the pipe at the set grade value.

- Place the laser target: Place the laser target at the opposite end of the pipe from the pipe laser. This target is usually a piece of plexiglass on a stand. It can be helpful to place this piece before turning on the laser to avoid the potential of shooting the laser into someone’s eye, which can cause eye injuries and blindness.

- Adjust the laser: Turn on the laser and observe at the target end of the pipe. Use a radio-based remote to adjust the laser horizontally until the laser is centered on the bullseye of the target.

Make sure you double-check any calculations before starting work, regardless of the quality of your pipe laser, and compare results with any project plans.

What’s a Pipe Laser Blower and Why do I need One?

A pipe laser blower is essential for those challenging jobsite conditions that can cause a pipe laser beam to “bounce” or “refract”. Refraction of a laser beam happens when the air temperature in the trench or pipe rapidly changes or when there is a large amount of fine dust in the trench. Some areas of the country see this in extreme hot weather and other areas experience refraction in extremely cold weather. Since a laser travels through the air old fashioned physics comes into play.

Job site tips for the proper use of a pipe laser blower:

As a contractor readies the pipe for installation, they typically lay the pipe end to end on the ground before lowering it into the trench. As the pipe lies in the sun, the top portion heats up, when installed into the cool dirt trench a drastic change of temperature occurs that can cause pipe laser beam refraction. This can also happen when the outside air above the trench is colder than in the trench. The cold pipe lowered into a warm trench can cause a rapid change in temperature in the pipe and cause laser refraction. This refraction makes it difficult to align the laser and can cause an alignment drift.

The contractor can do the following to alleviate laser drift and refraction: 1) Rotate the pipe when installing into the trench so that the top that was facing the sun is now contacting the dirt trench. This will help “even out” the temperature in the pipe and reduce drastic drift or refraction.

2) Install a Spectra Precision Pipe Laser Blower model 929 at the laser end of the pipe. Use the chart on the face of the blower to select the proper fan speed based on the size of the pipe and the length of the run. The proper air circulation will “homogenize” the air in a way that will alleviate any beam bounce. WARNING do not use just any air blower for this process! Too much, or misdirected air will only cause more refraction. The 929-pipe laser blower has a unique angled hose end, louvers and variable speed blower to ensure the air “swirls” in the pipe to eliminate refraction and restore proper beam position. Depending on the pipe run and size of the pipe it can take up to 20 minutes of fan circulation to settle the beam back into position.

Get the Right Equipment From SITECH Southwest

Pipe lasers are cost-effective investments, decreasing the burden on workers in sewer and underground pipe applications. By offering an easy-to-use and highly accurate leveling method, pipe lasers effectively reduce work time and simplify the survey process. If you’re interested in improving your company’s job success rate and finances with reliable construction technology solutions, SITECH Southwest is here to help.

As a Spectra Precision partner, SITECH Southwest distributes multiple Spectra pipe lasers in Arizona and Southern California for excavation applications. This includes the Spectra Precision DG813, DG613 and DG613G pipe laser models, all of which are easy to set up and offer top-notch functionality to maximize efficiency in construction projects. With these pipe laser models and assistance from our industry professionals, construction and utility companies can simplify the process of laying pipes while increasing their productivity and profits.

Not sure which model will work best for your application? Our experienced customer representatives can match you with the right innovative solutions for your construction project. Using our wealth of experience in providing, maintaining, servicing and repairing construction technology systems, we optimize each construction site solution to help your business minimize operational and repair costs. We also back our products with a comprehensive set of services, such as preventive maintenance, upgrades, repairs and equipment training courses.

At SITECH Southwest, our top priority is ensuring you have the technology and support you need to achieve the results you desire. With our quality pipe laser equipment, you can maximize your team’s potential. Call 602-600-0214 or contact us online today to learn more.